Introduction to Metal Matrix Composites for Foundries

The genius who first put straw into mud to make a better building material for early housing was probably the original inventor of composites. Assuming that there was good patent protection, he would have certainly retired a rich man. Years later, the same idea was upgraded to prestressed concrete (concrete reinforced and put in compression with steel rebar) which is one of the most widely used building materials in the world. A Samurai sword is a composite made by folding two different compositions of steel over and over to achieve millions of layers which impart unique properties to the blade. Eskimos use moss as a fibrous reinforcement to strengthen ice when used as a building material. There are examples all around us in nature of composite structures which exist to enhance the performance of or for living organisms.

The basic concept is to integrate a reinforcement material into a matrix material to obtain properties not possible from either material on their own. There are nearly an infinite number of combinations to be made to create composites which may be metal, ceramic or polymer-based, but for our discussion here it will be limited to metals as the matrix material. The major alloy groups that have been used as matrix materials are aluminum, beryllium, iron, magnesium, nickel, titanium, and tungsten. Reinforcement materials fall into two groups – continuous or discontinuous. Continuous reinforcements are continuous fiber structures made of carbon, aluminum oxide, silicon carbide or other compositions. Discontinuous reinforcements can be particles, chopped fibers or whiskers which are made of boron, boron carbide, silicon carbide, graphite, alumina and titanium carbide to name the major candidates.

Not all of these reinforcement components are readily wettable by the matrix metals that are good matches from a design perspective. Some metals will wet and then proceed to attack the reinforcement. Because of this the process of bringing the metal into contact with the reinforcement to produce a superior composite is an important step. The most commonly used routes are stir casting, pressure and pressureless infiltration, spray forming, and powder metallurgy (PM). In some cases, feedstock is formed at this step and in others a product ready for finishing results. Where additional forming is necessary, many times conventional equipment can be used with some modifications.

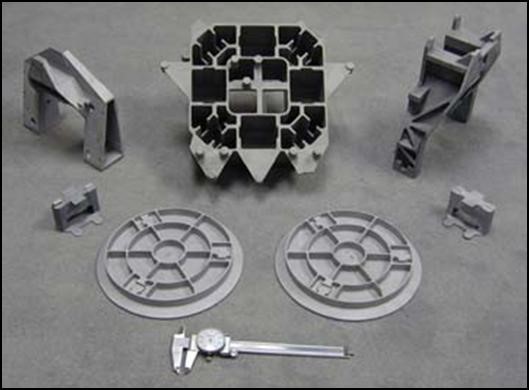

Figure 1: Investment cast Al/SiC-30p parts for precision applications

Sand, investment, die and squeeze casting are in use. Drive shafts have been made by extruding aluminum/silicon carbide billets. The powder metallurgy approach mixes metal powders and the reinforcement which is subsequently pressed into a billet and then shaped by extrusion or forging. In some cases, the powders are pressed into a shape and sintered. Wound continuous fiber forms can be infiltrated under great pressure (e.g. 10 – 20 atm.) in a pressure caster with metals ranging from aluminum alloys to titanium. All of these come at an associated cost which not only plays an important part in the properties of the end product, but its feasibility to the customer.

Sand, investment, die and squeeze casting are in use. Drive shafts have been made by extruding aluminum/silicon carbide billets. The powder metallurgy approach mixes metal powders and the reinforcement which is subsequently pressed into a billet and then shaped by extrusion or forging. In some cases, the powders are pressed into a shape and sintered. Wound continuous fiber forms can be infiltrated under great pressure (e.g. 10 – 20 atm.) in a pressure caster with metals ranging from aluminum alloys to titanium. All of these come at an associated cost which not only plays an important part in the properties of the end product, but its feasibility to the customer.

So, one might ask, “why all of the fuss”? Why don’t we just make a better alloy or add a new heat treatment to get the extraordinary properties that the designers need. The answer is that there have been great advancements in alloy development, but you can’t achieve the combinations of properties without going to a composite. For example, a company is designing a piece of equipment that carries out thousands of precise, minute operations on a single piece. A table on which the part sits must move quickly to a location, perform the operation, and then move to the next location. The competition is using a traditional material that is heavy, but dependable (think cast Invar). If you want to gain an edge on your competitor, you need a material that has the stiffness and coefficient of thermal expansion (CTE) of steel, but the weight of aluminum (think cast unobtainium or beryllium). With this material in your equipment, it has greater precision and the cycle time is greatly reduced – the customer wants it. This combination of properties, however, can’t be found in conventional materials, but it can be created in a composite of aluminum and silicon carbide particles.

The physical and mechanical properties of composites are dependent on the properties, geometry and concentration of the constituents. Increasing the volume content of reinforcements can increase the strength and stiffness of a composite to a point.

Table 1: MMC Product Design Considerations

| Gains | Losses |

| Increased specific strength | Reduced toughness |

| Increased specific stiffness | Reduced ductility |

| Improved elevated temperature strength | Reinforcement-matrix reactions |

| Improved wear resistance | Reduced machinability |

| Light weight | Higher material costs |

| Reduced thermal expansion coefficient | Lack of sufficient design data |

| Improved corrosion resistance | Joining and repairs may be difficult |

| Selective direction of properties (anisotropic) | Reduced recyclability |

| Fatigue resistance may increase | Fatigue resistance may decrease |

Properties can be tailored in composites to fulfill specific requirements, although, none of these requirements are accomplished without some compromise. As can be seen in Table 1, there are the upsides and the downsides to be balanced. It is not uncommon to develop a material with fantastic performance, yet the cost is too high to commercialize. There are also many cases in which all the gains are in the right direction and the designers (and the customers) can deal with the loss column. Some examples of products that have found a strong position in the marketplace are shown in Table 2.

Table 2: Metal Matrix Composite Applications

| Application | Composite | Benefit |

| Train Brake Rotors | Sand Cast Aluminum/Silicon Carbide | Lightweight, fuel savings |

| Naval Clutch Drums | Centrifugally cast aluminum bronze/tungsten carbide | Reduces clutch maintenance, eliminates asbestos |

| Electronic Thermal Management | Pressure Infiltrated aluminum/silicon carbide | Thermal conductivity, low CTE, high stiffness |

| Nuclear Containment | Rolled aluminum/boron carbide | Boron is an efficient neutron absorbent |

| Advanced Aerospace | Pressure Infilitrated titanium/silicon carbide filter | High specific strength and stiffness at elevated temperatures |

The global production of metal matrix composites is forecast to approach 6,000 Metric Tons by 2013 with revenues of $500 million (USD). An annual growth rate in revenues of 10% is expected to continue through the same time period. Aluminum-based MMCs will account for 60% of the total weight, but only 20% of the revenues because of its relatively low cost. Refractory metals, nickel, titanium and others will fill out the balance at much higher costs per pound. Aluminum-based composites can vary from $2.00 to $100 per pound in price depending on the processing method and type of reinforcement. Finished nickel-based composites can range in price from $135 to $170 per pound in a finished form. Titanium-based composites are among the most expensive at $1,500 per pound with continuous fiber reinforcement to $200 to $300 per pound for particle reinforced product.

If you take the long view on composites, metal matrix composites as a class of engineering materials have a short history of about 50 years. While the mud and straw approach still has practical use in some less developed countries, the rest of the world is embracing the application of more advanced composites. As designers become more comfortable and knowledgeable of metal-based composites, innovation and the desire to gain the competitive edge is driving the use of these materials.

By: Ken Kremer, Michael Waggoner, and Matthew Watkins