2023 Annual Report

Integrated Casting Order Network (ICON)

Integrated Casting Order Network (ICON)

Foundries supporting America's warfighters

The Non-Ferrous Founders Society (NFFS) is committed to advancing the concerns and interests of the non-ferrous metalcasting industry. This is underscored in part by our Integrated Casting Order Network (ICON) program. ICON is an innovative procurement solution, driving value to the Defense Logistics Agency (DLA) and domestic metalcasters by providing daily sales opportunities to domestic foundries in support of our nation's military and the American warfighter. Visit icon.nffs.org for additional information.

In 2023, the ICON program completed its five-year effort known as the "Innovative Casting Technology" (ICT) program under the American Metalcasting Consortium program with the Defense Logistics Agency. A brief summary of the ICON program's successes under the ICT program include:

- Cumulative Value:

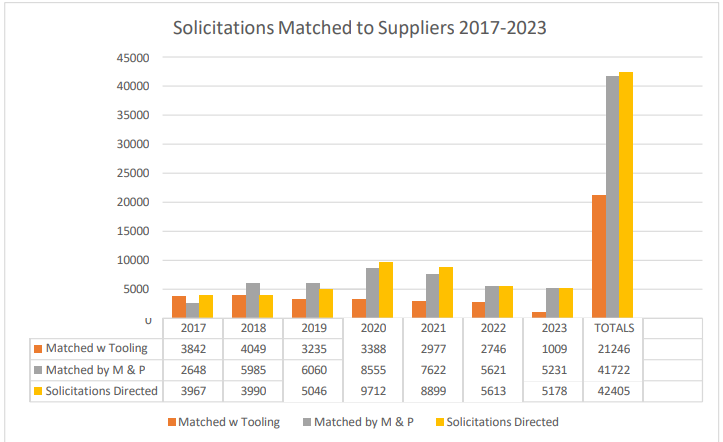

- More than 42,000 sales opportunities have been announced to ICON users since 2017.

-

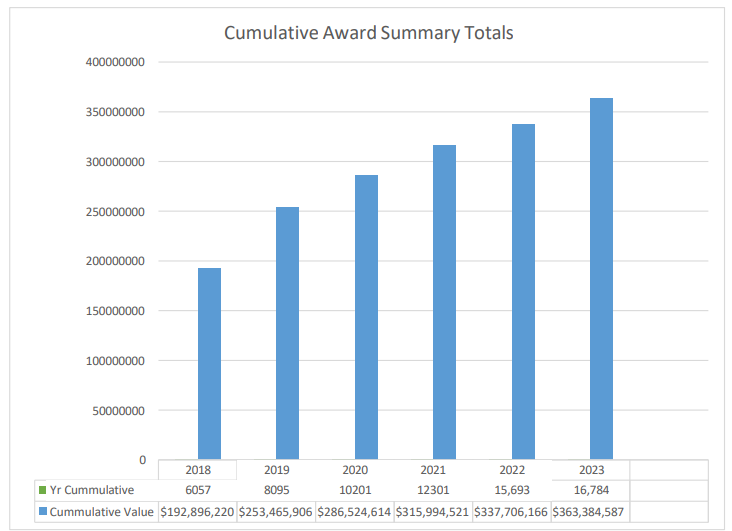

- A total of 16,784 contracts worth more than $363,000,000, have been awarded to ICON users since 2017. Contracts awarded to ICON users continue to increase and provide DLA with a larger competitive supplier base of metalcasters. Up to 38% of total available DLA contracts containing a cast metal component are being awarded to ICON users as reflected below:

- Cumulative Direct Cost Savings to DLA resulting from program

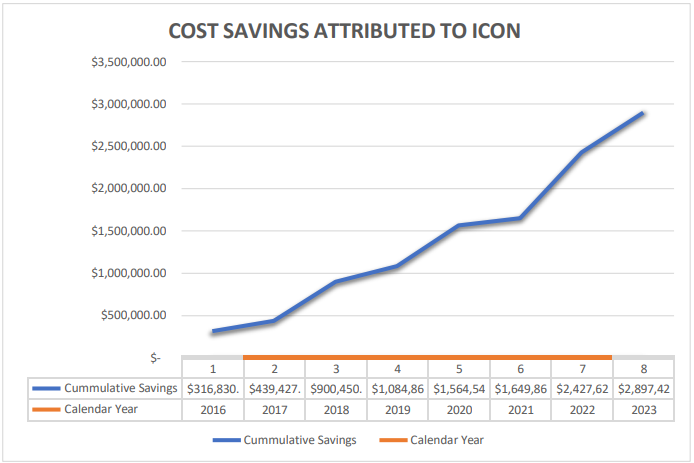

- ICON generated more than $2,897,426 in direct cost savings for the Defense Logistics Agency by establishing competitive supply chains for components, resulting in increased competition and actual cost reductions in per unit costs.

- Other Data

- There are more than 1,182 organizations participating in the ICON program, including foundries and machine shops.

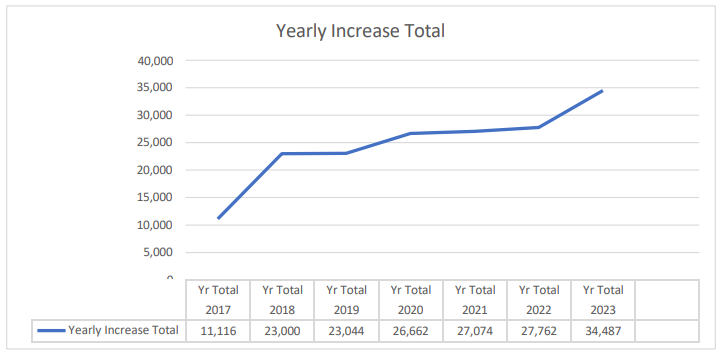

- ICON is home to the nation's most comprehensive defense and military foundry tooling database with more than 34,000 defense/military related tooling records available. The graph below represents the historical growth of over 34,000 tooling records in the ICON database showing that the total number of tooling records increased by 23,371 during the period of 2017-2023.

- ICON Success Story

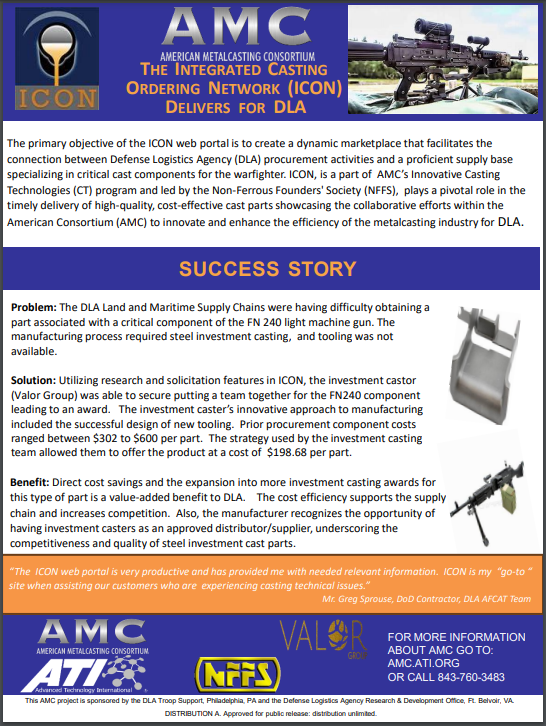

- ICON was able to reestablish the supply chain for a critical component of the FN 240 Machine Gun, leading to a cost reduction of more than 30% to DLA for the component and establishing a reliable domestic supply source for the part for future needs. DOWNLOAD

- Other noteworthy accomplishments by ICON program users during the ICT program:

- D.W. Clark, a Massachusetts-based foundry, learned of an open solicitation for a Half-Sleeve Bearing component to support the Ohio-Class nuclear-powered ballistic missile Trident submarine. Through the use of ICON, D.W. Clark received the award for the cast components. Also, by utilizing multiple features of the ICON portal, D.W. Clark was able to provide the component for 25% less, at an approximate savings of $35,000 versus previous procurements of the same order quantity;

- Danko Arlington, a Maryland-based foundry, received a small quantity requirement award from DLA for a critical spare part for the Howitzer M-109 weapon system. Danko was able to competitively bid on this transverse Mechanism Adapter sand casting using the A356.0-T6 alloy resulting in a one-time total cost savings of $1,875. Utilizing ICON, Danko was able to also receive a much larger volume of qualified business opportunities in a fraction of the time compared to using traditional search methodologies.

- Solidiform Inc., a Texas-based foundry, through the use of ICON enabled DLA to expand its sourcing base for the Nose Landing Gear Bumper Assembly. Using ICON’s solicitations inbox of directed business opportunities allowed Solidiform to quickly respond and allowed DLA to realize a cost reduction of approximately $275,000 on the first competitive procurement.

- Arimon Technologies, a Wisconsin-based metalworking machinery manufacturing facility, was able to quickly research an ICON-directed open solicitation for a Patriot Weapon System Cable assembly, power electrical component. This effort resulted in the first prime contractor opportunity for Arimon, promoted competition, and led to an award to a Service Disabled, Veteran, and Native American-owned small business.

Ultimately, the ICON portal has provided a valuable solution that links capable metalcasting foundries, machine shops, procurement specialists, and suppliers with the procurement needs of the DLA, resulting in reduced costs and lead times for these difficult-to-procure items. As the number of suppliers in the ICON portal increases, and more military-related tools are identified within the casting industry, the effectiveness of ICON will continue to increase. Future efforts include increasing the number of foundries using the ICON portal who can find and fulfill DLA bid solicitations for castings and continuing to add to the defense tooling database as additional defense and military-related tooling is discovered within the industry.

![]() For more information about ICON and its impact, visit our website at icon.nffs.org.

For more information about ICON and its impact, visit our website at icon.nffs.org.